FAF Products

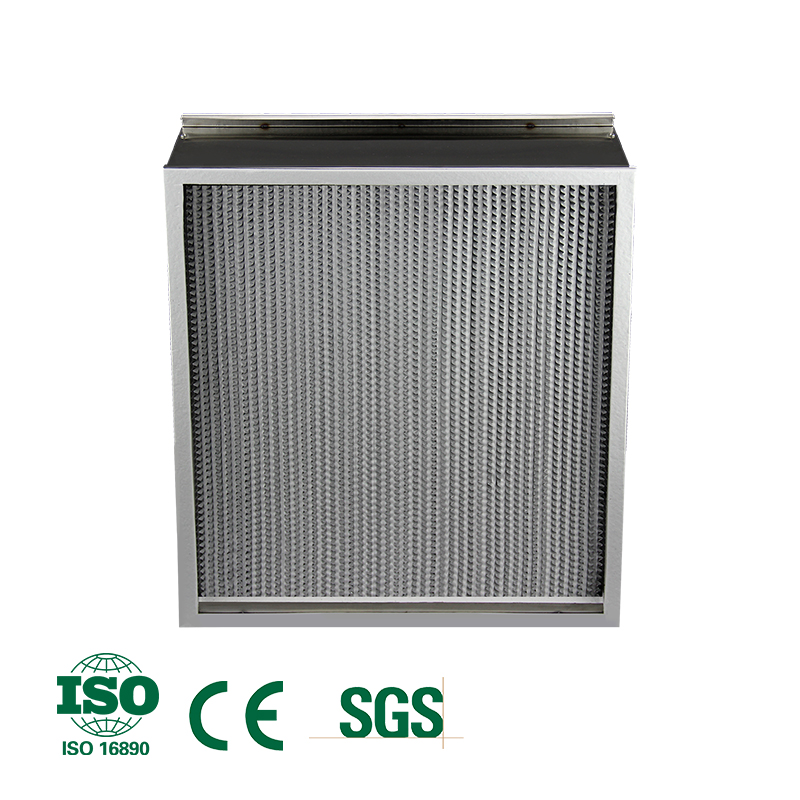

350℃ High temperature filters for pharmaceutical industries

Product information

The entire range is divided into the categories for up to 120, 250, and 350 degrees.

FAF HT 350C adopts innovative structural design, which is suitable for high temperature environment requiring long continuous operation and strict safety requirements.

Through the enhanced sealing of the filter element and the reinforcing frame, it always maintains the H14 level in the production process of the "high temperature zone", while achieving zero emission, zero tempering and zero cleaning.

The operating temperature of FAF HT 350C is up to 350 ° C, and the peak temperature can be up to 400 ° C.

The filter is scanned piece by piece in strict accordance with EN 1822:2009.

Core application process

1. Dry Heat Sterilization System

Application equipment: Depyrogenation Tunnel, Dry Heat Sterilization Cabinet

effect:

Remove endotoxins from glass bottles (penicillin bottles, ampoules) that can withstand high temperatures up to 350 ℃ and kill pyrogens.

Filter the particles in the hot air to ensure that the sterilized container achieves Class A cleanliness (ISO Level 5).

Technical parameters:

Working temperature: 250-350 ℃ (peak up to 400 ℃).

Material: Stainless steel 316L frame+fiberglass filter paper (PTFE coated).

2. Fluid Bed Drying/Granulation

High temperature airflow filtration:

Prevent the leakage of API particles with exhaust gas during the drying process (meeting GMP requirements for cross contamination control).

Typical case: Treatment of antibiotic particle drying exhaust gas.

3. Waste gas incineration and RTO (Regenerative Thermal Oxidizer)

VOCs treatment:

Filter the particulate matter in the exhaust gas containing organic solvents (such as ethanol and acetone) to protect the thermal storage body of the incinerator.

Corrosion resistance requirements: Must withstand acidic gases (such as HCl, SO ₂).

Special process requirements

| Process steps | Filter function | Compliance standards |

| Production of sterile injections | Sterilization tunnel air outlet filtration | EU GMP Annex 1(2022) |

| Extraction of Traditional Chinese Medicine | High temperature exhaust purification of concentrated evaporator | Requirements for volatile oil testing in the Chinese Pharmacopoeia |

| biopharmaceuticals | Fermentation exhaust gas sterilization (moisture and heat resistance+high temperature) | FDA 21 CFR Part 211 |

Specifications

|

Application |

High temperature ovens in pharmaceuticals and clean process manufacturing. |

|

Filter Frame |

SS304 or Aluminum |

|

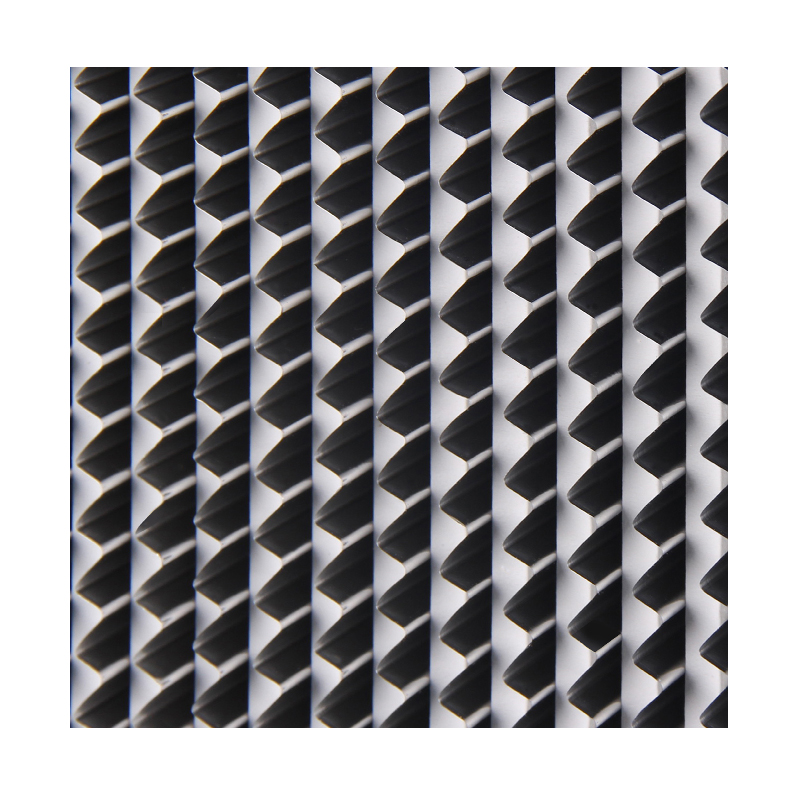

Media |

Glass fiber |

|

Max Temp °C (Peak) |

400° C, 750° F |

|

Relative Humidity |

90% |

|

Separator |

Glass fiber |

|

Gasket |

Braided glass fiber |

|

Comment |

99.99% at 0.3 micron. |

Key indicators for selection and maintenance

selection

1. Filtration efficiency: H13-H14 grade (≥ 99.95% -99.995% for 0.3 μ m particles).

2. Structural strength: It needs to withstand frequent high-temperature cooling cycles (thermal expansion and contraction without delamination).

3. Chemical compatibility: Acid and alkali resistant (such as NaOH/HNO ∝ used for CIP cleaning).

maintenance

1. Regular leak detection: PAO/DOP method testing (at least once a year, mandatory by EMA/FDA).

2. Replacement cycle: usually 2-3 years (or when the pressure difference is ≥ twice the initial value).

3. Document records: The filter number, installation date, and leak detection report should be retained (for auditing purposes).

Case: A multinational pharmaceutical company used 350 ℃ high-temperature resistant HEPA at the exhaust end of a freeze dryer, reducing particle emissions to<1 μ g/m ³ and successfully passing the FDA on-site inspection.

By accurately matching process requirements, high-temperature and high-efficiency filters can ensure both drug sterility and environmental compliance.

FAQ

Q: What Payment term you are running?

A:50% deposit paid in advance,50% of the balance is paid before delivery.

Q3. How about your delivery time?

A: Generally, it will take 7 to 15 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q: Do you provide samples? Is it free or extra?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.