FAF Products

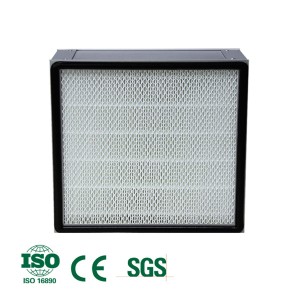

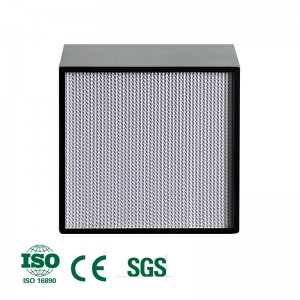

EPA, HEPA & ULPA Mini-pleated Filters

Why us

FAF’s clean air solutions help to protect sensitive advanced manufacturing processes, prevent microbiological contamination in research labs, and eliminate infectious airborne contaminants in the healthcare sector.

FAF’s air filters are tested with the IEST Recommended Practice for Testing HEPA Filters (RP-CC034), to ISO Standard 29463 and EN Standard 1822.

FAF’s air filters protect the people involved in the processes and ensure the integrity of what is being produced to reduce financial risks. In the healthcare industry, FAF’s HEPA air filters are the main barrier of defense against infectious transfer so facility patients, employees, and visitors are not compromised.

FAF’s HEPA and ULPA air filter panels are designed for terminal filtration in applications ranging from cleanrooms and semiconductor fabrication to the food and beverage industry and pharmaceutical manufacturers.

FAF’s HEPA and ULPA air filters are efficient and energy-saving plate filters designed for nonunidirectional flow and unidirectional flow applications in clean rooms, clean workbenches and clean equipment.

Filters are widely used in industries where cleanliness needs to be strictly controlled, with efficiency grades

The advantages of our products

Ranging from H13 to U17, and MPPS efficiency ranging from 99.95% to 99.999995%.

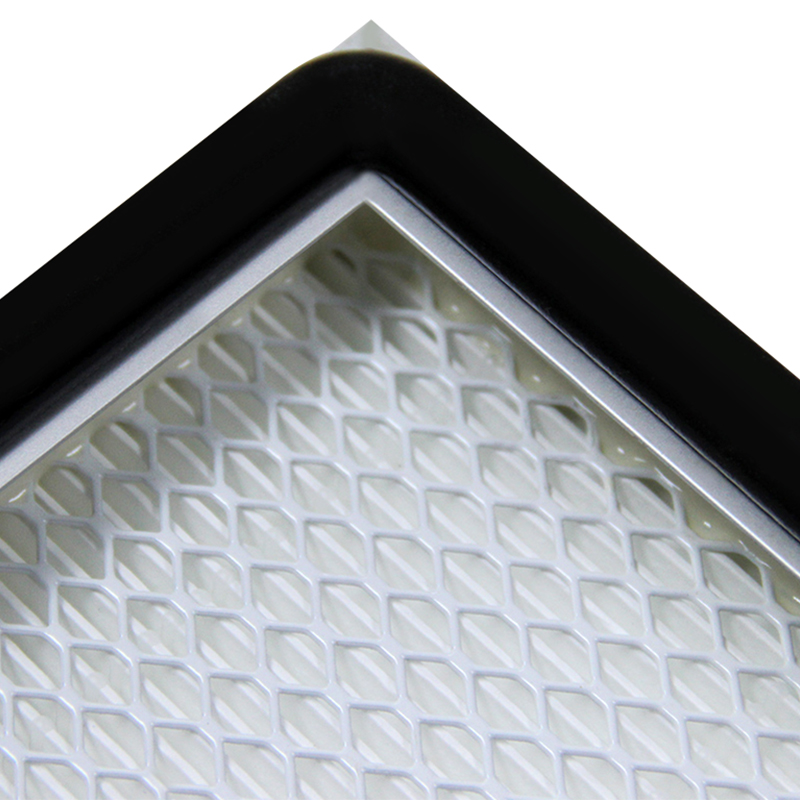

Special controlled pitch origami process and point breaking hot melt adhesive process are adopted to form rigid support and ensure uniform filter fold spacing.

The filter element and filter frame are fixed with polyurethane sealant.

The frame is made of anodized aluminum with built-in corner code to ensure durability and long-term integrity. Avariety of filter gaskets can be selected: integrated polyurethane, EDPM, PU tank seal and Silicone tank seal. The filters have passed the standard test, and are scanned piece by piece according to EN 1822 to obtain the air volume, resistance and efficiency parameters, and provide the serial number on the product label.

• Applicable to the application needs of clean rooms and equipment in microelectronics industry

• Ideal nanoparticle filtration (0.1um)

• High dust capacity

• Filter passes 100% scanning test to ensure stable performance

• The test can be carried out according to EN1822, IEST or other standards

• Each filter is attached with an independent test report

• Zero leakage guaranteed

• Test aerosol free of organic volatile matter

• Low volatile adhesives and gaskets (no organic flame retardants)

• Manufacturing and packaging in a clean room environment

FAQ

1. Can you accept sample orders?

We can.

2. What is your packaging?

Can be packaged according to customers actual requirements if you need.

3. How long is your delivery time?

The stock out of the warehouse is 2-5 days, 100 standard products, about 10-15 days.