FAF Products

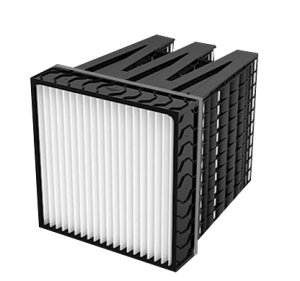

Gas Turbine Panel Air Filters

Gas turbine plate filters are deeply loved by the market because of their larger air volume, smaller installation space, and good protection for terminal filters.

Product Feature &Application scenarios

1)Using new hydrophobic composite material, low resistance and long service life

2)Low wind resistance, wind resistance rises slowly under humid conditions

3)Hydrophobic and droplet separation provides waterproofing and drainage

4)Better protect the final filter and extend its service life

5)Pre-filters for most turbomachinery and gas turbine applications

Composition materials & operating conditions

1)Frame: Plastic

2)Media: Composite new materials

3)Dividers: Plastic inserts

4)Sealant: Polyurethane AB type sealant

5)Gasket: Polyurethane foam seamless gasket

Common specifications, models & technical parameters

|

Model |

Size(mm) |

Air flow(m³/h) |

(Pa) Initial resistance |

Efficiency |

Media |

|

FAF-RC-18 |

287*592*96 |

1800 |

20~45Pa |

G4/F5/F6 |

Composite new materials |

|

FAF-RC-36 |

592*592*96 |

3600 |

Note: It can be customized according to user specifications and technical parameters.

FAQ

Q1:Why Choose FAF for Gas Turbine Filters?

A1:We have 20 years of experience in filter manufacturing. Professional engineers will solve your air purification problems. The factory has passed ISO9001 and ISO14001 certification and can provide high-quality filter products.