FAF Products

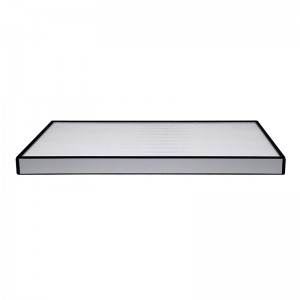

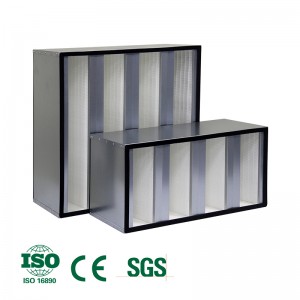

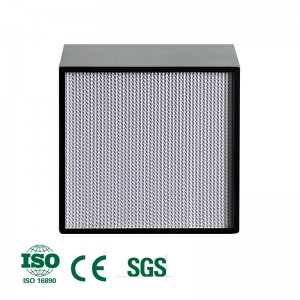

Mini Pleat HEPA Filter for Cleanroom

The Features and applications of the Air Purifier Mini Pleated HEPA Filter

Features:

●Low resistance

●High air flow rate

●Light weight

●We can make the non-standard size filter or different filter requirements according to the client's requirement.

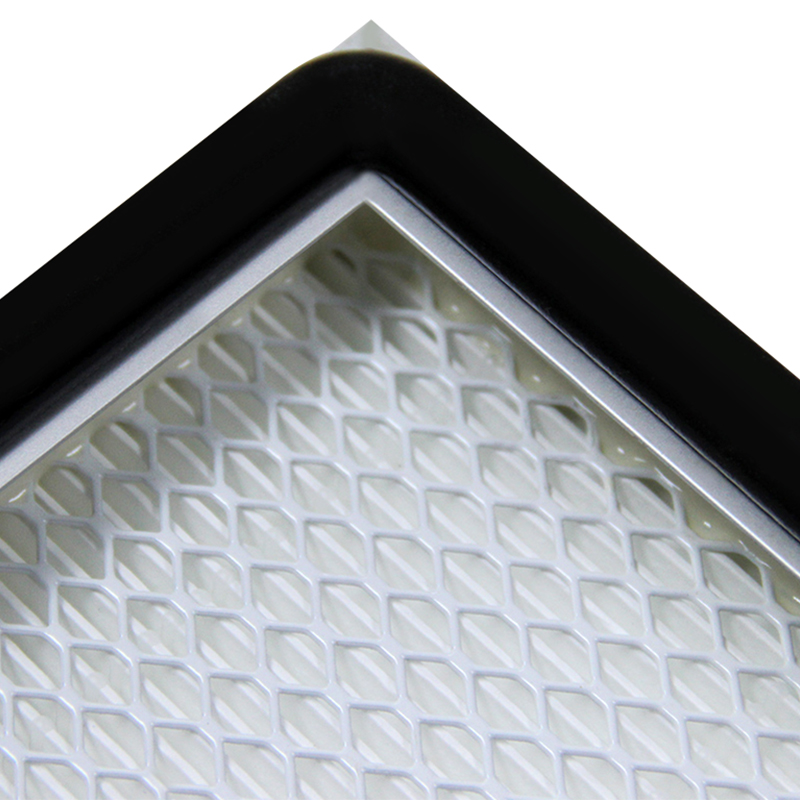

●Aluminum frame can anti-corrosion for long time.

●Sealant around the media prevent the air filter is without any air leaking.

Application:

Widely used in electronic industry, pharmaceutical industry, food industry and the clean bench.

Product photography of the Air Purifier Mini Pleated HEPA Filter

|

Size |

customized size and design are available |

|

Efficiency |

H13/H14 |

|

Max. temperature |

80℃ |

|

Max. humidity |

80% |

|

Filter media |

glass fiber paper |

|

Frame |

aluminum plate, galvanized sheet plate, stainless steel |

|

Aluminum profile optional thickness |

46mm, 50mm, 69mm, 80mm, 90mm, 96mm |

Parameter of the Air Purifier Mini Pleated HEPA Filter

| Model | Outer dimension (mm) | Rated Air Flow (m³/h) | Resistance (Pa) | Efficiency |

| FAF-WGX-3 | 305*305*69 | 150 | ≤220 | ≥99.99% |

| FAF-WGX-4 | 457*457*69 | 350 | ||

| FAF-WGX-5 | 570*570*69 | 500 | ||

| FAF-WGX-5.5 | 610*305*69 | 300 | ||

| FAF-WGX-6 | 610*610*69 | 600 | ||

| FAF-WGX-9 | 915*610*69 | 900 | ||

| FAF-WGX-10 | 1170*570*69 | 1000 | ||

| FAF-WGX-12 | 1220*610*69 | 1200 | ||

| FAF-WGX-14 | 1220*610*80 | 1400 | ||

| Customized | ||||

Complies with VDI 6022

Microbial inert components according to ISO 846

Conform to EC 1935:2004 food contact requirements

BPA, phthalate and formaldehyde free

Resistance to chemical inactivators and cleaners

Applicable to the application needs of clean rooms and equipment in microelectronics industry

Compact energy-saving products

Filter passes 100% scanning test to ensure stable performance

The test can be carried out according to EN1822, IEST or other standards

Each filter is attached with an independent test report

Zero leakage guaranteed

Test aerosol free of organic volatile matter

Low volatile adhesives and gaskets (no organic flame retardants)

The material does not contain any dopant

Manufacturing and packaging in a clean room environment

Why us

1. Representative filter from each batch type and production run are subjected to a complete test flow evaluation to determine efficiency, pressure drop and dust holding capacity.

2. To ensure that ex-factory products are maintained in perfect condition and are not damaged during transport to final destination.

Q&A

1.How does a mini pleat HEPA filter work?

- The filter uses a dense mat of randomly arranged fibers to trap particles as air passes through. The mini pleat design maximizes the surface area, enabling the filter to capture 99.97% of particles as small as 0.3 microns, including dust, pollen, mold spores, bacteria, and other airborne contaminants.

2.Are mini pleat HEPA filters effective against viruses

- HEPA filters can capture particles as small as 0.3 microns, including some viruses. However, viruses alone are often smaller than 0.3 microns but are typically attached to larger particles (like droplets), which HEPA filters can effectively capture.