Chemical filter materials are essential components in various industries and applications, playing a crucial role in removing impurities and contaminants from liquids and gases. These materials are designed to effectively capture and neutralize harmful substances, making them an indispensable part of filtration systems. In this article, we will explore what chemical filter materials are, their characteristics, and their application scenarios.

What is Chemical Filter Material?

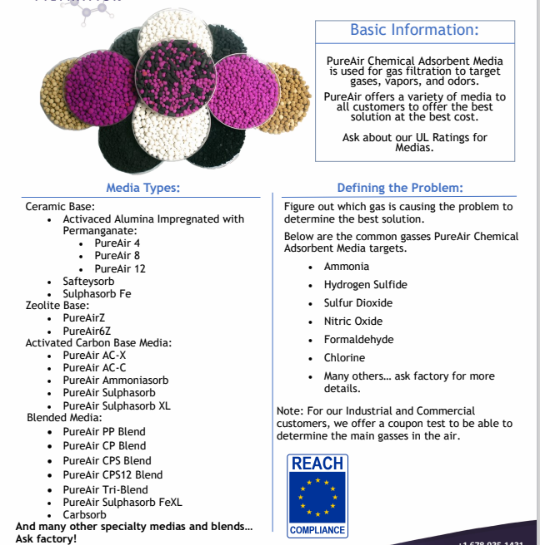

Chemical filter materials are substances specifically designed to remove or neutralize impurities, contaminants, and pollutants from liquids and gases. These materials are engineered to have high adsorption and absorption capacities, allowing them to effectively capture and retain a wide range of substances, including organic and inorganic compounds, heavy metals, and other harmful pollutants. Chemical filter materials can be made from various substances, including activated carbon, zeolite, silica gel, and various synthetic polymers, each offering unique properties and capabilities for specific filtration needs.

Characteristics of Chemical Filter Material

Chemical filter materials possess several key characteristics that make them highly effective in filtration applications. One of the most important characteristics is their high surface area, which provides ample space for adsorption and absorption of contaminants. Additionally, these materials often have a porous structure, which further enhances their capacity to capture impurities. Their chemical composition and surface properties also play a significant role in determining their adsorption capabilities, making them suitable for a wide range of filtration requirements. Furthermore, chemical filter materials are often designed to be chemically stable and resistant to degradation, ensuring their long-term effectiveness in various operating conditions.

Application Scenarios of Chemical Filter Material

Chemical filter materials find extensive use in diverse industries and applications due to their versatile nature and high filtration efficiency. Some common application scenarios include:

1. Water Treatment: Chemical filter materials are widely used in water treatment systems to remove contaminants such as chlorine, organic compounds, heavy metals, and other pollutants, ensuring the production of clean and safe drinking water.

2. Air Purification: In air filtration systems, chemical filter materials are employed to capture and neutralize harmful gases, odors, and volatile organic compounds (VOCs), improving indoor air quality in residential, commercial, and industrial settings.

3. Industrial Processes: Various industrial processes, such as chemical manufacturing, pharmaceutical production, and wastewater treatment, utilize chemical filter materials to remove impurities and ensure the purity of liquids and gases used in these processes.

4. Environmental Remediation: Chemical filter materials play a vital role in environmental remediation efforts, such as soil and groundwater remediation, by effectively capturing and immobilizing contaminants to mitigate environmental pollution.

5. Gas Separation: In gas separation applications, chemical filter materials are utilized to selectively remove specific gases from gas mixtures, enabling the purification and separation of valuable gases for industrial use.

In conclusion, chemical filter materials are indispensable components in filtration systems, offering high efficiency in capturing and neutralizing contaminants in liquids and gases. With their diverse characteristics and versatile applications, these materials play a crucial role in ensuring the purity and safety of various processes and environments across different industries. As technology and material science continue to advance, the development of innovative chemical filter materials will further enhance their capabilities and expand their potential applications in the future.

Post time: May-30-2024