-

Chemical gas-phase cylindrical filters cassette

FafCarb CG cylinders are thin-bed, loose-fill filters. They provide optimum removal of moderate concentrations of molecular contamination from supply, recirculation, and exhaust air applications. FafCarb cylinders are noted for their extremely low leakage rates.

FafCarb CG cylindrical filters are engineered to provide the highest level of performance in Indoor Air Quality (IAQ), comfort and light-duty process applications. They utilize a high weight of adsorbent per unit airflow with only moderate pressure loss.

-

Chemical gas-phase filters cassette with activated carbon

FafCarb VG Vee cell air filters are thin-bed, loose-filled products. They provide efficient removal of acidic or corrosive molecular contamination in outdoor air and recirculation air applications.

FafCarb VG300 and VG440 Vee cell modules are engineered for high performance in process applications, especially those that require preventing corrosion of electrical control equipment.

VG modules are manufactured from engineering-grade plastic with welded assembly. They can be filled with a wide range of molecular filtration media to provide broad-spectrum or targeted adsorption of contaminants. Model VG300 in particular, utilizes a high weight of adsorbent per unit airflow.

-

V-Bank Air Filter with Activated Carbon Layer

The FafCarb range is perfect for indoor air quality (IAQ) applications that require the efficient control of both particulate matter and molecular contamination using a single compact air filter.

FafCarb air filters contain two distinct layers of pleated media formed into panels that are held in a robust injection molded frame. They operate with Rapid Adsorption Dynamics (RAD), which ensures high removal efficiency of multiple low to moderate concentrations of contaminants found in urban buildings. A large media area ensures high efficiency, long life, and low pressure drop. Filters are readily mounted in standard 12” deep air handling unit frames and are built with a jointless gasket on the header to ensure leak-free operation.

-

V Type Chemical Activated Carbon Air Filters

The FafSorb HC filter is designed for the effective removal of common indoor and outdoor gaseous contaminants at high airflows, to help mitigate Indoor Air Quality problems. The FafSorb HC filter is suitable for retrofit into existing HVAC systems and for specification in new construction. It can be used in equipment designed for 12″-deep, single header filters.

-

Auto Air Shower of Clean Room

- To use the high-speed clean air to blow off the dust that enters the cleanroom personnel’s surface.

As cleanroom equipment, installed in the clean room entrance and used to remove the dust on personnel or goods entering through it.The principle of the Auto air shower

To use the high-speed clean air to blow off the dust on workers into the clean room.

Usually installed in the clean room entrance and used to remove the dust through air shower system.

- To use the high-speed clean air to blow off the dust that enters the cleanroom personnel’s surface.

-

Class 100 Vertical Air Flow Clean Bench

-

- Open loop air circulation is as follows, the main feature is that in each cycle all the air is collected from the outside through clean bench box and returned to the atmosphere directly. The general horizontal flow super-clean working table adopts the opening loop, this kind of clean bench structure is simple, cost is low, but the fan and filter load are heavily, it has a bad effect on using life, at the same time the cleaning efficiency of fully open air circulation is not high, usually only for low cleanliness requirements or biological hazards environment.

-

-

DC EFU Equipment Fan Filter Unit for Cleanroom

-

- The equipment fan filter Unit (EFU) is an air filtration system that includes a fan to provide a constant flow of clean air.

EFUs are highly versatile and can be used in a variety of applications, including cleanrooms, laboratories, and data centers. They are highly effective at removing particulate matter and other airborne contaminants, making them an ideal choice for environments where air quality is critical.

- The equipment fan filter Unit (EFU) is an air filtration system that includes a fan to provide a constant flow of clean air.

-

-

DC FFU Fan Filter Unit for Clean Room

-

- A Fan Filter Unit (FFU) is a self-contained air filtration system that is commonly used in cleanroom environments to remove contaminants from the air. It typically consists of a fan, a filter, and a motorized impeller that draws in air and passes it through the filter to remove particles. FFUs are commonly used to create positive air pressure in cleanrooms, and are also used in other applications that require clean air, such as in healthcare facilities and laboratories.

-

-

Replaceable HEPA Box Filter for Cleanrooms

Disposable and replaceable type are available for users to choose from

Closed design is adopted to prevent internal gaps and side leakage, so as to meet the strict requirements of clean room for air qualityThe diameter of the air inlet pipe is 250mm and 300mm or customized, and the height of the pipe is 50mm or customized. It can be directly connected to the air pipe, and there is a metal protective net in the air inlet pipe to protect the filter material of the high-efficiency filter;

The replaceable HEPA Box is made of lightweight aluminum frame. The air outlet surface is equipped with high-quality galvanized sheet, which is beautiful and light, which helps to reduce the handling and installation time;

PEF or insulation cotton is used for insulation on the surface, with good insulation performance.

The integrated air supply outlet can select high-efficiency filters with different efficiency according to the requirements of customers

Each high-efficiency integrated air supply outlet has been tested one by one before leaving the factory to ensure the performance index of the high-efficiency air filter, and various high-efficiency air filters with non-standard specifications and filtration requirements can be made according to user requirements.

-

Terminal HEPA filter housing for ceiling installation

-

- A terminal HEPA filter housing is a device used in cleanroom environments to filter and clean the air that is circulated through the room. HEPA stands for High Efficiency Particulate Air, which means that these filters are capable of trapping extremely small particles, including bacteria, viruses, and other microorganisms.The terminal HEPA filter housing is typically installed at the end of the air handling unit (AHU) and is responsible for capturing any contaminants that may have been missed by previous filters in the air handling system. It is designed to provide a high level of filtration efficiency, ensuring that the air that enters the cleanroom is free from particles and contaminants.

-

-

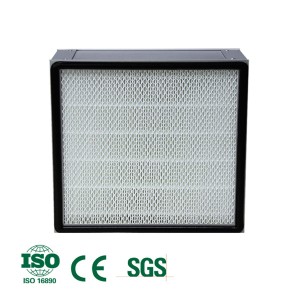

Mini Pleat HEPA Filter for Cleanroom

1. Representative filter from each batch type and production run are subjected to a complete test flow evaluation to determine efficiency, pressure drop and dust holding capacity.

2. To ensure that ex-factory products are maintained in perfect condition and are not damaged during transport to final destination. -

EPA, HEPA & ULPA Mini-pleated Filters

FAF’s clean air solutions help to protect sensitive advanced manufacturing processes, prevent microbiological contamination in research labs, and eliminate infectious airborne contaminants in the healthcare sector. FAF’s air filters are tested with the IEST Recommended Practice for Testing HEPA Filters (RP-CC034), to ISO Standard 29463 and EN Standard 1822.

Customers in heavily regulated industries, with strict quality requirements, trust FAF’s EPA, HEPA, and ULPA filters. In manufacturing venues such as pharmaceutical, semiconductor or food processing, or critical laboratory services, FAF’s air filters protect the people involved in the processes and ensure the integrity of what is being produced to reduce financial risks. In the healthcare industry, FAF’s HEPA air filters are the main barrier of defense against infectious transfer so facility patients, employees, and visitors are not compromised.